Sumter Electric Company

The Sumter Electric Co. was one of if not the

largest supplier of magnetos to Fuller & Johnson. Replacing the

previously used Elkhart, Sumter mags equipped thousands of model N and K

engines in both rotary and oscillating versions. Rotary models

include 16, 21, 26, 30, JDC and B while the #14 was utilized for the

oscillator. Sumter generally made a good quality magneto.

One thing to watch for is the pot metal baseplate can over time expand

and throw of the critical alignment of the bearings as well as air gap

between the pole pieces and armature.

The little #16 magneto was used on the 1 1/2hp N and could be mounted in 2 ways, each being driven by the cam gear. The first required a special bracket and a longer camshaft. A boss on the bracket slipped over the camshaft inside the crankcase. The mag was affixed to the bracket with one large flathead screw, the assembly now being rotated to lay flat in the crankcase's top edge. Here was drilled one hole. A long bolt passed up thru this hole, thru a second hole in the bracket into the magneto's base. This firmly held the assembly to the engine. A shortened gear adapter was used with this setup. Later engines simplified this by doing away with the bracket and longer camshaft. The crankcase now had a slightly raised pad cast into it with the mag being affixed direct with two bolts. A slightly longer gear adapter was required and will not interchange with the earlier one. If necessary one or more paper shims would be placed under the magneto to adjust gear mesh. F&J advised the 1 1/2hp engines to be ordered from the factory with a magneto as it could not simply be installed in the field like the bigger engines.

Single bolt hole associated with the early style magneto bracket

A larger #21 magneto was used on engines 3 and 5hp engines and occasionally the 7hp too. The #26 was essentially just an updated version of the 21. It used a different system for bearing lubrication and the output was taken from the rear of the armature rather than a collector ring/brush setup from the top plate.

The #30 was frequently seen on 7, 9 and 12hp engines. It was essentially the same as the other mags just bigger. Another model used was the JDC. This was a very large and odd magneto and was constructed differently from other Sumters. It featured a pot metal body and rear bearing cap. Lead out from via a collector ring and brush on top rear of the armature housing. The large magnets were covered with an even larger brass band. The band's edges were actually wrapped over the magnet's edge. The tag was painted an orange color with a gold stripe running around its perimeter. Printed in gold was the following:

The little #16 magneto was used on the 1 1/2hp N and could be mounted in 2 ways, each being driven by the cam gear. The first required a special bracket and a longer camshaft. A boss on the bracket slipped over the camshaft inside the crankcase. The mag was affixed to the bracket with one large flathead screw, the assembly now being rotated to lay flat in the crankcase's top edge. Here was drilled one hole. A long bolt passed up thru this hole, thru a second hole in the bracket into the magneto's base. This firmly held the assembly to the engine. A shortened gear adapter was used with this setup. Later engines simplified this by doing away with the bracket and longer camshaft. The crankcase now had a slightly raised pad cast into it with the mag being affixed direct with two bolts. A slightly longer gear adapter was required and will not interchange with the earlier one. If necessary one or more paper shims would be placed under the magneto to adjust gear mesh. F&J advised the 1 1/2hp engines to be ordered from the factory with a magneto as it could not simply be installed in the field like the bigger engines.

Single bolt hole associated with the early style magneto bracket

A larger #21 magneto was used on engines 3 and 5hp engines and occasionally the 7hp too. The #26 was essentially just an updated version of the 21. It used a different system for bearing lubrication and the output was taken from the rear of the armature rather than a collector ring/brush setup from the top plate.

The #30 was frequently seen on 7, 9 and 12hp engines. It was essentially the same as the other mags just bigger. Another model used was the JDC. This was a very large and odd magneto and was constructed differently from other Sumters. It featured a pot metal body and rear bearing cap. Lead out from via a collector ring and brush on top rear of the armature housing. The large magnets were covered with an even larger brass band. The band's edges were actually wrapped over the magnet's edge. The tag was painted an orange color with a gold stripe running around its perimeter. Printed in gold was the following:

SUMTER

WATERPROOF

TYPE JDC

PATS PENDING

GUARENTEED

FOR THE

LIFE OF THE ENGINE

MADE IN THE USA BY

SUMTER

ELECTRICAL CO.

WORKS SUMTER, S.C

SECONDARY OFFICE

CHICAGO, ILL.

WATERPROOF

TYPE JDC

PATS PENDING

GUARENTEED

FOR THE

LIFE OF THE ENGINE

MADE IN THE USA BY

SUMTER

ELECTRICAL CO.

WORKS SUMTER, S.C

SECONDARY OFFICE

CHICAGO, ILL.

This is the same magneto often supplied to New Holland

and having NEW HOLLAND name prominently printed on the band.

The JDC has been found on a 6hp N Kerosene and a 7hp K engine and presumably a very

small number were used on that size as well as the 9 and

12hp.

The Sumter JDC

The Sumter JDC

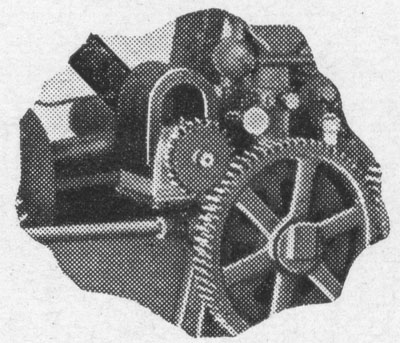

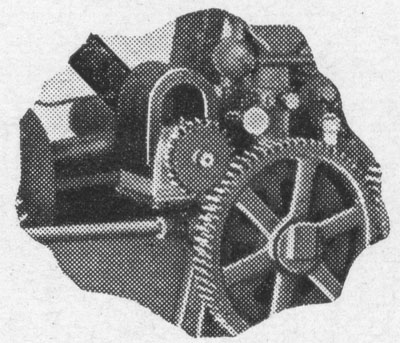

The large model B was used on the impressive 15, 20 and

25hp model K engines and was driven off the cam gear.

It was standard equipment and if not wanted a $25 credit

would be issued on the engine's purchase price. A gear

adapter similar to those on the smaller engine was used with

magneto.

A Sumter B magneto assembly

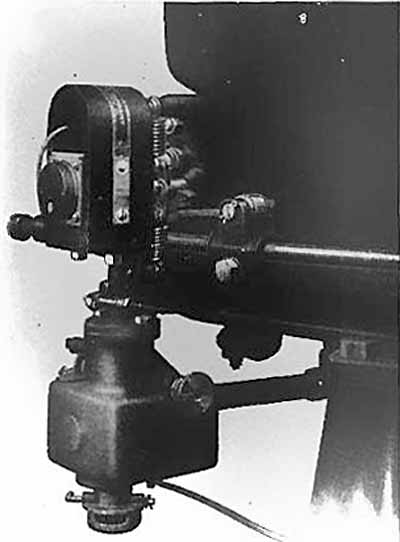

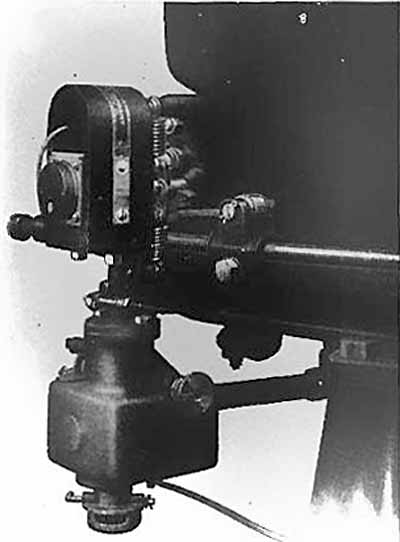

Sumter also supplied a complete plugoscillator using the #14 magneto. The advantage of an oscillating magneto over a rotary is that its output is independent of the engine's speed. No matter the engine's speed, magneto output was always 100% and the starting batteries could be dispensed with. Besides the magneto Sumter also manufactured the ignitor plug, the part number being N1. By having the trip and spring arms on the bracket it relieved the magneto of considerable torsional stresses. Sumter even supplied their special trip finger which featured an early/late spark advance to aid starting. Unlike the previous Wizard oscillator F&J did not use the Sumter oscillator very extensively and it is quite rare to find a surviving engine equipped with one.

1918 illustration from a Sumter plugoscillator article in the Oil Field Engineer

The Sumter N1 Plugoscillator, note the special trip finger with early/late ignition cam

A Sumter B magneto assembly

Sumter also supplied a complete plugoscillator using the #14 magneto. The advantage of an oscillating magneto over a rotary is that its output is independent of the engine's speed. No matter the engine's speed, magneto output was always 100% and the starting batteries could be dispensed with. Besides the magneto Sumter also manufactured the ignitor plug, the part number being N1. By having the trip and spring arms on the bracket it relieved the magneto of considerable torsional stresses. Sumter even supplied their special trip finger which featured an early/late spark advance to aid starting. Unlike the previous Wizard oscillator F&J did not use the Sumter oscillator very extensively and it is quite rare to find a surviving engine equipped with one.

1918 illustration from a Sumter plugoscillator article in the Oil Field Engineer

The Sumter N1 Plugoscillator, note the special trip finger with early/late ignition cam

| HOME |