OIL COOLED

The Oil Cooled "Frost-Proof" was the first

engine to be manufactured and sold by Fuller & Johnson. It was

designed by Frank D. Winkley who at the time worked for Gisholt Machine

Tool which was founded by John A. Johnson. A small number of these

engines were built at Gisholt and sold under the name Madison Gas

Engine. 1902 was the first year the line was introduced in 1 1/2,

3 and 6hp sizes. By the end of 1903 the two smaller sizes were

re-rated to 2 and 3 1/2hp while the 6hp remained the same. These

engines were heavily built featuring large split hub flywheels, an

enclosed crankcase and hit miss governing with the weights being located

in the large cam gear. A fuel pump fed an overflow mixer and

initially dual ignition was provided by a hot tube and electric ignitor

with the former being dropped on later engines. The two larger

sizes also had mechanically operated intake and exhaust valves using a

clever pull/pushrod system operated by a single cam.

Adding to the engine's substantial weight was the unique oil cooling system. A cast iron steam radiator was fitted to an extension of the sub base and piped to the engine's cooling jacket. An expansion tank was provided and some engines were also fitted with a circulation pump. The entire system was filled with a light mineral oil making for a truly frost proof cooling system. This however made not only for a heavy engine but an expensive one. A more traditional and cheaper water tank cooled version was offered and the 6hp size was even offered as a hopper cooled engine. This odd variation briefly became the 6hp Double Efficiency.

Adding to the engine's substantial weight was the unique oil cooling system. A cast iron steam radiator was fitted to an extension of the sub base and piped to the engine's cooling jacket. An expansion tank was provided and some engines were also fitted with a circulation pump. The entire system was filled with a light mineral oil making for a truly frost proof cooling system. This however made not only for a heavy engine but an expensive one. A more traditional and cheaper water tank cooled version was offered and the 6hp size was even offered as a hopper cooled engine. This odd variation briefly became the 6hp Double Efficiency.

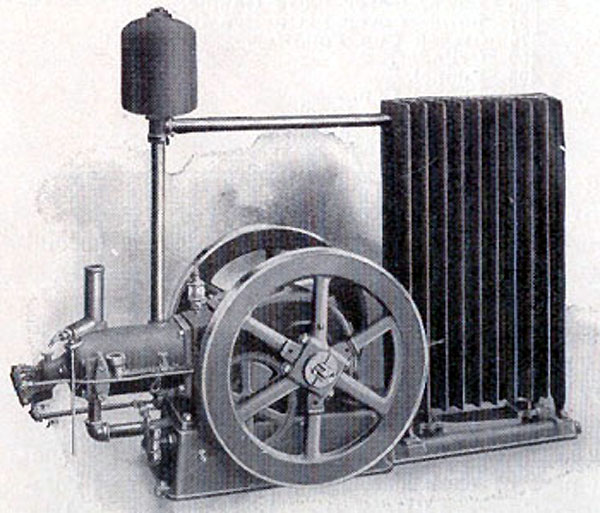

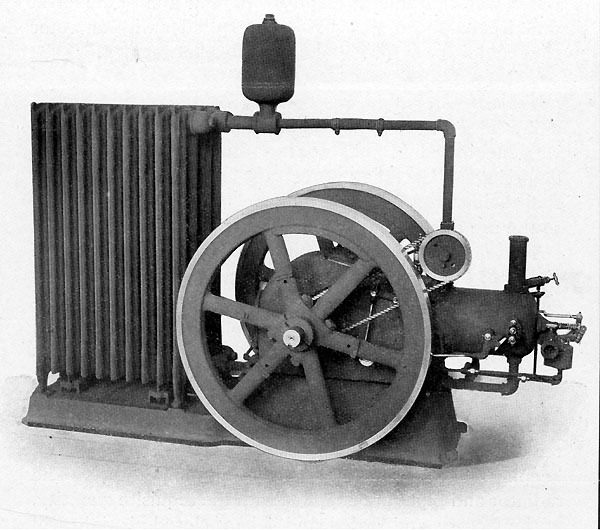

A 3hp Oil Cooled stationary engine.

A factory built pumping unit powered by a 1 1/2hp engine. Note the dual ignition systems.

The mighty 6hp Oil Cooled featured dual cooling radiators and an oil circulating pump.

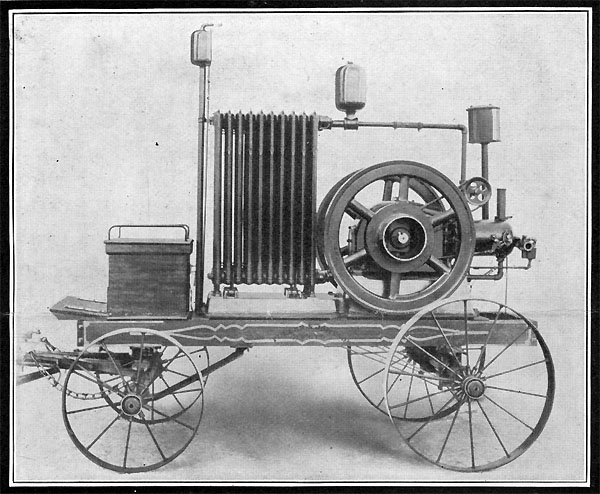

Mounted on a high set of team trucks this 6hp portable is an impressive looking piece of machinery.

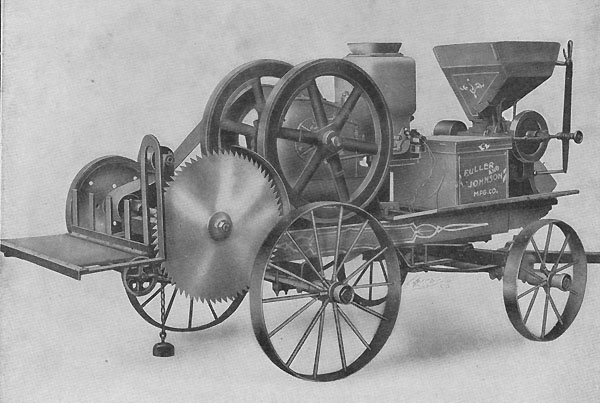

A hopper cooled 6hp engine on a factory built combined sawing and grinding outfit.

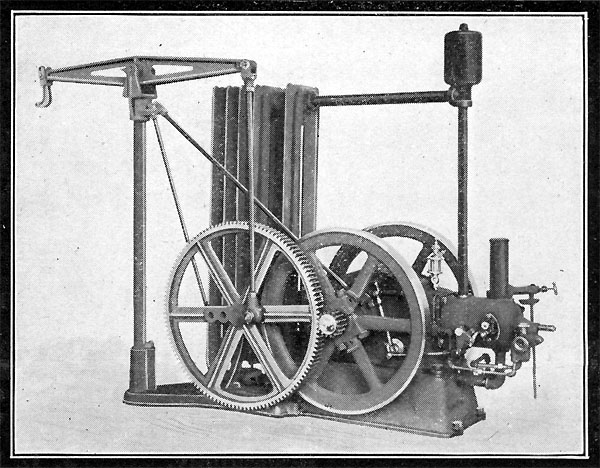

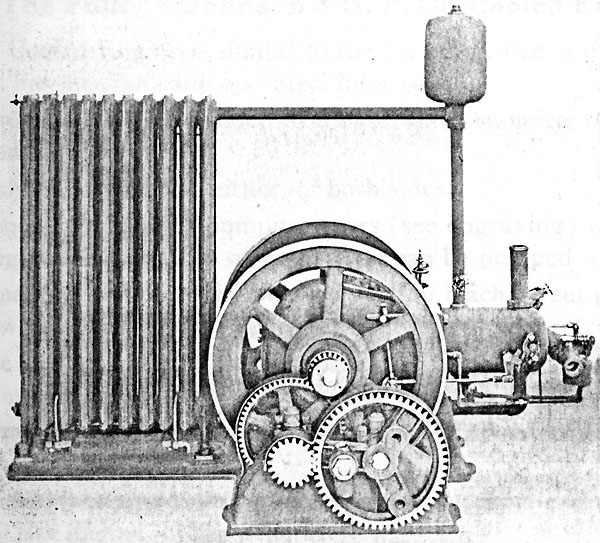

This double gear reduction pumping unit was intended for heavy duty pumping service.

| HOME |